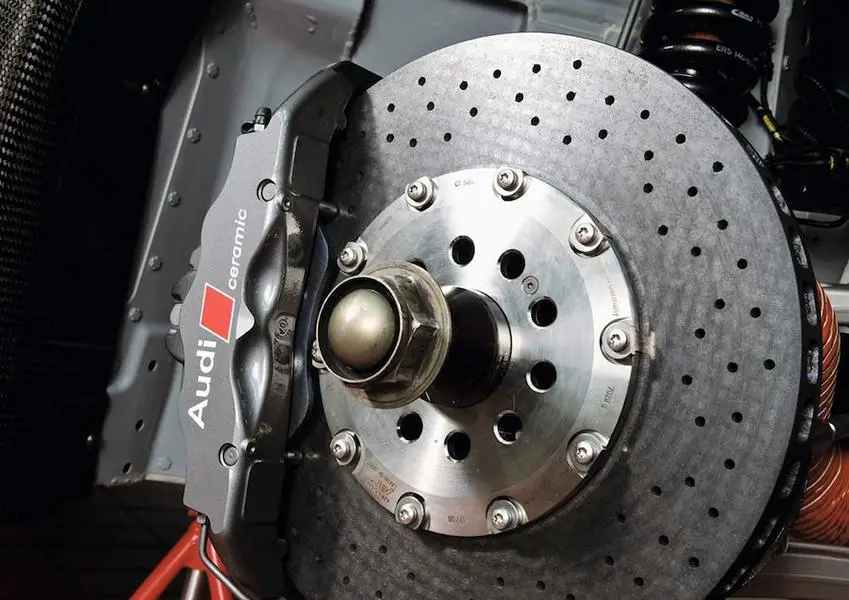

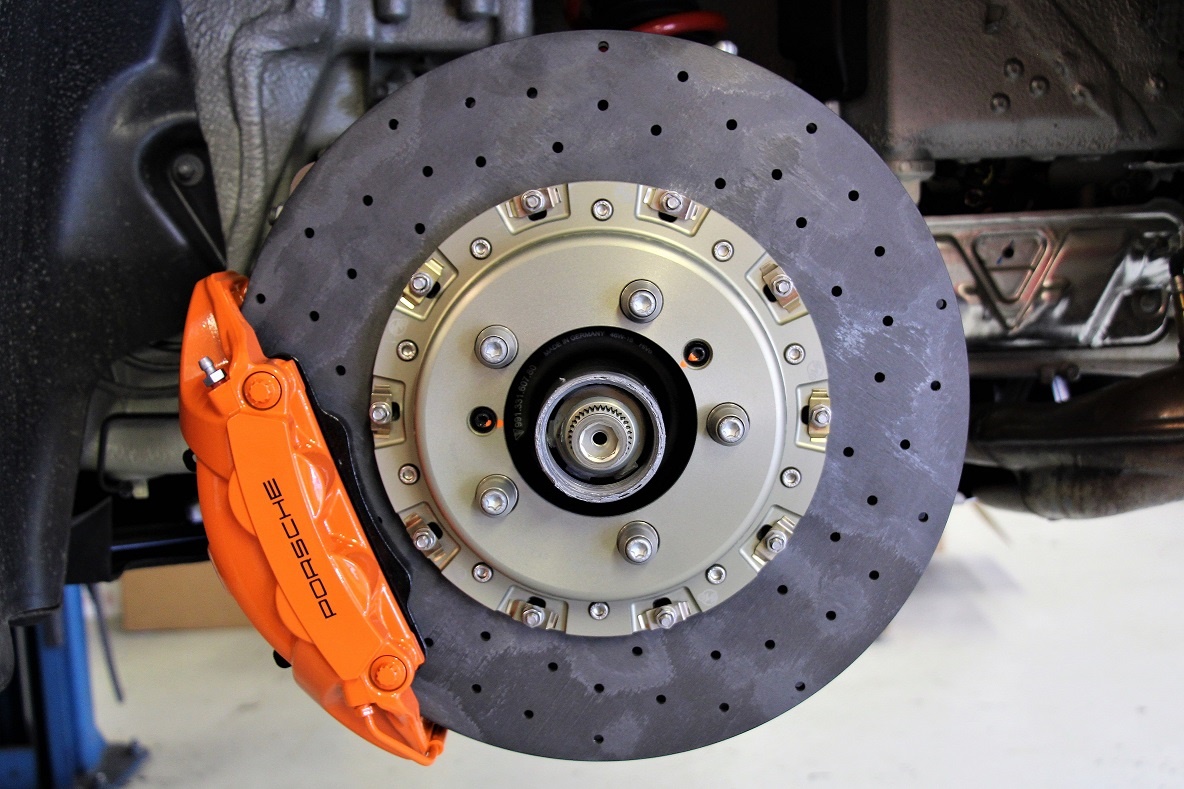

Carbon ceramic brakes are actually designed to withstand the usual intense heat that occurs during braking.

Changing from ceramic brakes to carbon fiber ceramic brakes.

This is because the material they re made from is much less reactive than steel and iron due to the material s tightly bonded structure.

The advantages of the ceramic brake pad mixture are reduced noise less wear and less brake dust that cleaning the rims is less common.

When replacing and servicing conventional brakes the special brake pads can still be worthwhile.

According to brembo this heat resilience cannot be easily replicated with the usual.

Manufactured for severe duty friction ferro carbon provides between 20 to 40 percent more stopping power and a high resistance to brake fade.

Power stop z36 1399 truck tow carbon fiber ceramic front brake pads power stop s z36 brake pads are designed for heavy duty vehicles like trucks.

Refurbish for extended life a newly developed process allows for the refurbishment of ccs rotors as long as carbon content in the rotors meets the required levels.

Ferro carbon 2 brake pads.

Best for heavy duty vehicles.

The special pad mixture of such brake pads only has ceramic friction agents but not the carbon fiber reinforced silicon carbide of the known carbon ceramic brakes.

A carbon rotor will have better heat properties.

Carbon ceramic brakes on the other hand are virtually immune to corrosion.

The carbon ceramic formulation is designed as a significant performance upgrade for most high performing and luxury street cars.

What forum members are saying about carbon ceramic brakes.

Finally carbon ceramic brakes are much cleaner and quieter than conventional steel brakes.

The tires in this case michelin pilot sport cup 2 are the limiting factor in braking distance thresholds.

There is no distance advantage for the carbon cars even with the extra downforce that the z07 package provides.

Extensive testing has revealed performance characteristics friction profile strength fade and heat management that match or surpass oem carbon ceramic matrix rotors.

The carbon ceramic brakes fitted as standard on many high performance vehicles are constructed in one of two ways either a core of ceramic material reinforced with chopped carbon fibre with an additional ceramic layer on the friction surface or simply the core of ceramic material with chopped carbon fibre and no outer friction layer.